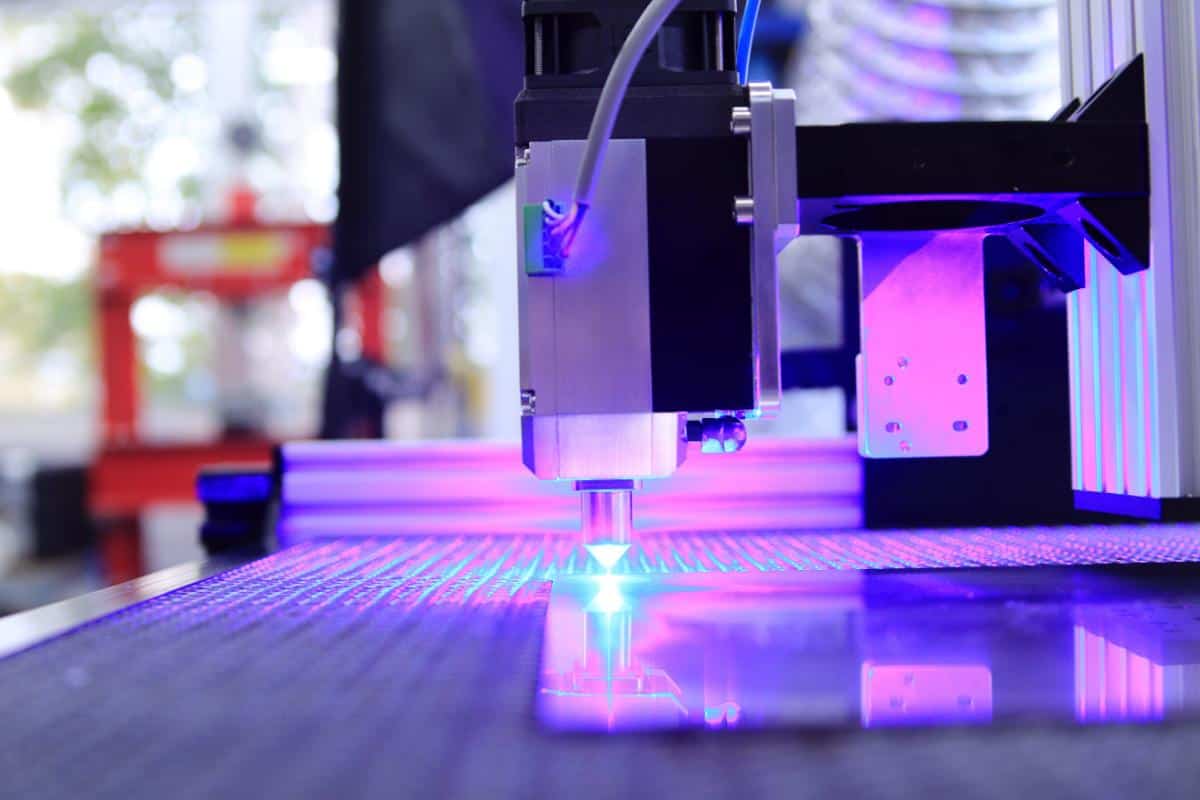

Why CNC Laser Cutting Is Perfect For Intricate Design Work

This is a collaborative post.

Designing with fine detail can be challenging when using traditional tools. Even the most skilled hands can struggle with shapes that demand microscopic precision.

CNC laser cutting solves this problem by combining advanced machinery with pinpoint accuracy. If you’re keen to see why this process is trusted for complex designs, keep reading to find out the reasons that prove its value.

Precision That’s Hard To Match

CNC laser cutting produces sharp and accurate edges with a level of detail that manual cutting can’t achieve. The laser focuses on a small area, allowing for cuts measured in fractions of a millimetre. This level of control ensures that patterns remain consistent, even on projects that require repeated production runs.

Versatility Across Different Materials

The process works on a wide range of materials, including stainless steel, aluminium, acrylic, and wood. This flexibility means that you can create detailed signage, decorative pieces, or industrial parts without switching between different machines. That’s why many firms now rely on CNC laser cutting to achieve reliable results without compromising material choice.

Reduced Material Waste

When working with expensive materials, waste can be a serious cost factor. Using a trusted CNC laser cutting fabrication service reduces offcuts by optimising every cutting path.

This efficiency means you’re not throwing away as much raw material, which directly lowers overall costs. For businesses conscious about sustainability, using less material also supports environmental goals.

Ability To Handle Complex Shapes

Intricate design often involves curves, cut-outs, and repeating patterns that are difficult to achieve by hand. CNC laser cutting handles these shapes with ease. Whether you’re producing architectural panels or bespoke furniture pieces, the process ensures that every detail is captured. The result is consistent quality, no matter how complex the design appears on paper.

Faster Turnaround Times

Traditional cutting methods require tool changes and manual adjustments that slow down production. With CNC laser cutting, the process is automated and programmed directly from design software.

This not only speeds up manufacturing but also reduces the risk of human error. For businesses, faster turnaround translates to shorter lead times and greater competitiveness.

Clean And Polished Finish

Another advantage is the smooth edges produced during cutting. There’s no need for extensive finishing, as the laser leaves surfaces neat and free from burrs. This is particularly valuable in design work where appearance matters as much as function.

By reducing post-processing, you save both time and money while ensuring that the products look professional straight from the machine.

Closing Remarks

Intricate design doesn’t have to mean complex production problems. CNC laser cutting gives you accuracy, speed, and a professional finish, all while keeping costs under control.

From reducing waste to handling complex shapes, it proves itself as the ideal choice for designers and manufacturers who refuse to compromise on quality. When precision and creativity meet, CNC laser cutting stands out as the solution that delivers on both fronts.